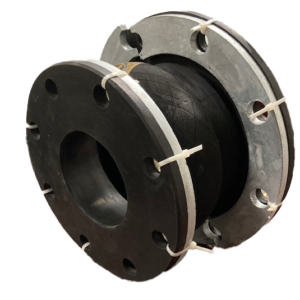

Rubber Expansion Joints for Piping Systems provide time-tested ways to accommodate pressure loads, relieve movement stresses, reduce noise, isolate vibration, compensate for misalignment after plants go on stream, and prolong the life of motive equipment. Flexible rubber expansion bellows are available in a variety of styles and elastomers and are used to convey fluid under vacuum pressure conditions in piping systems. Flanged rubber expansion joints are the most common type of rubber expansion bellows and are available in single – and multi-arch designs. They can be custom-engineered to fit your application requirements and we also have many flexible rubber bellow available from stock. Our rubber expansion joints are particularly beneficial due to their flexible nature, which makes them suitable for many functions, including the absorption of sound, thermal energy and shock. They are specifically designed to reduce the need for maintenance, repair and manual assistance in piping systems.

OTHER TYPES OF EXPANSION JOINTS:

Rubber Expansion Joint Styles

Super-Flex Wide Arch Design Style 1000

Superior Performance Characteristics

- MADE IN THE USA

- Premium Quality Performance

- Twice the capabilities of a standard arch

- Lower spring rates required for movement

- Fabric and steel reinforced

- Available in multi-arch, offset and special constructions

- 150lb drill pattern

- EPDM, Neoprene, Nitrile, Viton® & Other Elastomers

Boss-Flex Single Wide Arch Design Style 100

- Twice the capabilities of a standard arch

- Lower spring rates required for movement

- Fabric and steel reinforced

- Available in multi-arch, offset and special constructions

- 150lb drill pattern

- EPDM, Neoprene, Nitrile, Viton® & Other Elastomers

Maximum deflection, elongation and compression.

- Minimizes water hammer and hydraulic shock

- Less force to move; allows maximum movements

- “All-in-one” design eliminates the need for retaining rings

- Available in Twin Sphere design for greater movement capabilities

- Floating flange design provides easy installation

- EPDM, Neoprene, Nitrile, Viton® & Other Elastomers

Allows for greater movement

- Available to 20″ Diameter

- The twin-sphere 802 comes with steel 150lb ASA drilled flanges

- Floating flanges to provide easy installation

- Center root ring to meet PSI shown

- EPDM, Neoprene, Nitrile, Viton® & Other Elastomers

Joins piping systems with unequal pipe sizes

- Concentric for parallel piping

- Eccentric for offset piping

- Available in a wide variety of diameters

- Floating flanges to provide easy installation

- EPDM, Neoprene, Nitrile, Viton® & Other Elastomers

DuPont Kevlar® Reinforced Non-Metallic Expansion Joint

- Hand wrapped custom built construction to allow for design variations, while still offering wide arch movement

- Single, double, concentric and eccentric construction available

- Available in Viton®, EPDM, Butyl, Pure Gum and Nitrile

- Flanges are laser cut from carbon steel and other available alloys

Spool-Type Standard Arch Style 150

- The heavy duty proven “industry work horse”

- Time tested performer

- Fabric and steel reinforced

- Constructed for maximum strength and reliability

- Available in multi-arch, taper, offset and special constrictions

- EPDM, Neoprene, Nitrile, Viton® & Other Elastomers

Supreme Lightweight Application Design Style 189

- Lightweight construction

- Low spring rate forces

- Can be built to handle temperatures up to 350ºF

- Less force to move; allows maximum movements

- Available in multi-arch, taper, offset and for high temperature applications

- EPDM, Neoprene, Nitrile, Viton® & Other Elastomers

High Pressure Capable Supreme Style 200 (XL)

- Extra – reinforced carcass

- For pressures to 300 PSI

- Available in constructions suitable for temperatures to 400ºF

- Available in multiple arch, taper, offset and special constructions

- Available in wide arch for increased movement

- EPDM, Neoprene, Nitrile, Viton® & Other Elastomers

Combined Technology PTFE & Rubber Dura Perm

- The excellent chemical resistance of PTFE

- The flexibility of rubber expansion joints

- Thermal stability

- Anti-stick properties

- Available in multiple arch, taper, offset and special constructions

- EPDM, Neoprene, Nitrile, Viton® & Other Elastomers

- Absorb thermal movements and vibration in duct work

- Aids in the elimination of noises caused by scrubber equipment and mechanical dust collectors

- capable of handling any combination of large movements which might occur in a ducting system due to thermal expansion

- EPDM, Neoprene, Nitrile, Viton® & Other Elastomers

Twin-Sphere Style 803

- Designed for smaller pipes

- Highly capable

- Cost effective

- Often used in power plants, chemical plants, water works and sewage treatment facilities

- EPDM, Neoprene, Nitrile, Viton® & Other Elastomers

Radi-Flex Elbow Expansion Joint

- Designed to reduce noise and vibration

- Protects against thermal expansion over angles

- Spiraled steel wire embedded adds strength.

- Available in 45 degree and 90 degree configurations

- Flexibility prevents damage

- EPDM, Neoprene, Nitrile, Viton® & Other Elastomers

Vibration Absorbing Styles 2150 & 2250

- Specially designed lengths of rubber pipe with factory attached ferrules for pipes and other connections involving standard IPT

- Eliminates vibration between pump and pipeline either for suction or discharge

Vibration & Sound Absorbers Styles 3150 & 3250

- Designed with molded rubber flanged ends with bolt holes that accommodate standard steel flanges

- Fabricated with or without helical wire reinforcement.

- Special tubes can be compounded to meet unique service conditions in either suction or discharge applications

Standard Rubber Options for Expansion Joints

- EPDM

- Nitrile

- Neoprene

- Viton

Benefits of Flexible Rubber Expansion Joints

- Economy of minimal face-to-face dimensions

- Lightweight construction requires no special handling equipment

- Insulates against the transfer of noise and vibration

- Compensates for misalignment

- No electrolysis

- Greater recovery from movement

- Ease of Installation

- Small space requirements

- Low movement forces required

- Reduced fatigue factor

- Reduced heat loss

- Corrosion and erosion resistant

- No gaskets required

Changes in temperature and pressure in piping systems connected to pumps lead to thermal expansion and contraction within the pipes. Rubber expansion joints and connectors are the ideal choice for many piping situations, and they have several uses. Rubber expansion joints are most often used as a flexible connector between a vibrating piece of mechanical equipment and the pipeline. They can also be used to absorb pipe movements. Rubber connectors will also provide for a reasonable amount of pipe offset caused by equipment settling.

Available options include PTFE-lined, eccentric reducing, concentric reducing, filled arch, lightweight and off-set configurations. They can be designed to operate up to 200 psi and withstand temperatures up to 500º F. Sizes available from 1/2″ to 144″.

Careful selection of the expansion joint design and material for a given application, as well as properly engineered installation are important factors in determining performance. These factors should be fully evaluated by each person selecting and applying expansion joints for any application.

*Rubber expansion joints have been specified and used for many years by consulting engineers, mechanical contractors, pressure vessel designers, plant engineers and turnkey construction firms. They are installed to accommodate movement in piping runs, protect piping from expansion and contraction and insure efficient and economical on-stream operations.

Rubber expansion joints provide time-tested ways to accommodate pressure loads, relieve movement stresses, reduce noise, isolate vibration, compensate for misalignment after plants go on stream and prolong the life of motive equipment. Rubber expansion joints, designed by engineers and fabricated by skilled craftsmen, are used in all systems conveying fluids under pressure and/or vacuum at various temperatures:

• Air conditioning, heating and ventilating systems in commercial and institutional buildings, schools, apartments, stores, hospitals, motels, hotels and aboard ships.

• Central and ancillary power-generating stations in communities, factories, buildings

and aboard ships.

• Sewage disposal and water-treatment plants.

• Process piping in paper and pulp, chemical, primary metal and petroleum refining plants.

The Advantages of Rubber Expansion Joints and Flexible Connectors

The Rubber expansion joint industry has allied itself with designers, architects, contractors and erectors in designing and fabricating joints under rigid standards to meet present-day operating conditions. UIP has kept abreast of the technological advances in rubber compounding and synthetic fabrics to provide rubber expansion joints having advantages not available in other materials.

• Economy of minimal face-to-face dimensions

• Lightweight construction requires no special

handling equipment

• Insulates against the transfer of noise and vibration

• Compensates for misalignment

• No electrolysis

• Greater recovery from movement

• Ease of installation

• Small space requirements

• Low movement forces required

• Reduced fatigue factor

• Reduced heat loss

• Corrosion and erosion resistant

• No gaskets required

Why Use Rubber Expansion or Vibration Joints?

Three Basic Reasons for Their Use:

- To Prevent Stresses Due to Expansion and Contraction

- To Insulate Against the Transfer of Noise and Vibration

- To Compensate for Misalignment

Rubber or non-metallic expansion joints are flexible connectors fabricated of natural or synthetic elastomers, fluoroplastics and fabrics, and when necessary, metallic reinforcements provide stress relief in piping systems due to thermal and mechanical vibration and/or movements.

UIP Rubber Expansion Joints provide relief from stresses caused by thermal expansion and contraction in pipelines. Movement is always experienced in piping systems due to varying ambient temperatures, differences in temperature of materials handled, and differences in composition. Expansion joints absorb this movement and eliminate the danger

of buckling or pulling apart with the high replacement costs that would result.

Pumps, compressors and other pulsating equipment generate noise and vibration. The transmission of noise and vibration tends to reduce the efficiency of adjacent equipment and impairs working conditions in offices and plants. Expansion joints serve as reliable insulation against such vibration and noise.

Settlement, load stresses and normal wear of components will frequently cause piping and mechanical equipment to become misaligned.

Expansion joints can resolve these problems within their design limits. Special designed expansion joints are available for specific conditions and misalignment.

Engineers can solve anticipated problems of vibration, noise, shock, corrosion, abrasion, stresses and space by incorporating rubber expansion joints into designed piping systems.

Functions:

Reduce Vibration

Rubber expansion joints isolate or reduce vibration caused by equipment. Some equipment requires more vibration control than others. Reciprocating pumps and compressors, for example, generate greater unbalanced forces than centrifugal equipment. However, rubber pipe and expansion joints dampen undesirable disturbances including harmonic overtones and vibrations caused by centrifugal pump and fan blade frequency. This is based on actual tests conducted by nationally recognized independent testing laboratory. Rubber expansion joints reduce transmission of vibration and protect equipment from the adverse effects of vibration.

Dampen Sound Transmission

Subsequent to going on stream, normal wear, corrosion, abrasion and erosion eventually bring about imbalance in motive equipment, generating undesirable noises transmitted to occupied areas. Rubber expansion joints

tend to dampen transmission of sound because of the steel-rubber interface of joints and mating flanges. Thick-wall rubber expansion joints, compared with their metallic counterparts, reduce considerably the transmission of sound.

Compensate Lateral, Torsional and Angular Movements

Pumps, compressors, fans, piping and related equipment move out of alignment due to wear, load stresses, relaxation and settling of supporting foundations. Rubber expansion joints compensate for lateral, torsional and

angular movements, preventing damage and undue downtime of plant operations.

Compensate Axial Movements

Expansion and contraction movements due to thermal changes or hydraulic surge effects are compensated for with strategically located rubber expansion joints. They act as helix springs, compensating for axial movements.