OTHER TYPES OF EXPANSION JOINTS:

Custom Metal Expansion Joints in a Variety of Configurations to Suit Your Application

When selecting UIP International metal bellows expansion joints, you can be rest assured that these expansion joints are manufactured to the highest quality standards and are designed to last. Constructed from precision manufactured bellows and coupled with customer specified connections, our metal bellows expansion joints are available in a wide array of configurations to meet your needs. They are typically made from high quality steel components, commonly formed from fully annealed 321 stainless steel. Other grades of stainless steel as well as rare metal alloys may be offered dependent upon your application.

Steel Options include:

- 321 Stainless Steel

- T304/304L Stainless Steel

- T316/316L Stainless Steel

- Inconel 600/326/800/825

- Hastelloy C22/C276

Size Ranges Available

Most metallic bellows expansion joints are available from 2-1/2″ diameter up to 100″ diameter in ether single or multi-ply. Single ply bellows available in thicknesses of .008″ to .125″. Multi-ply are available in thicknesses up to .160″ combined wall thickness.

End Connections

FIXED FLANGES

Type 44 ends are plate steel flanges conforming to ANSI dimensions welded directly to the integral ends of the bellows. Stainless steel and other alloys are available when specified.

FLOATING FLANGES

Type 66 ends are flat face plate flanges conforming to ANSI dimensions, secured to the integral end of the bellows flared (Vanstoned) to retain the flanges. This allows the use of carbon steel flanges when the only wetted parts will be the stainless steel of the bellows. It also permits easy bolt hole alignment.

WELDING NIPPLES

Type 22 ends are carbon steel welding nipples with ANSI standard bevel. Schedule 40 pipe size is used through 12″ diameters. 1/4″ wall thickness for sizes over 12″ unless otherwise specified.

We Carry All Types of Metal Expansion Joints

Applications Include:

- Diesel Engine Exhaust

- Diesel Generator Exit and Boiler Flue

- High and Low-Pressure Turbine Piping

- Main Feed Pump Suction

- Propeller Shaft Air System

- Condensate Pump Suction

- Saturated and Superheated Steam

Single Bellows Weld Ends

Weld end metal bellow expansion joints have sections of pipe attached to each end of the bellows intended for welded installation. This style’s design has a flangeless installation and excellent sealing properties.

Single Bellows Fixed Flanges

Fixed flange metal bellows expansion joints are constructed with raised face or plate flanges welded to the end of the bellows. Fixed flange ends require knowledge of bolt hole alignment for each end it will be installed. This style is best suited for Class-D applications.

Single Bellows Raised Face Flanges

Raised face flange metal bellows expansion joints are provided with Class 150 drilling or Class 300 drilling carbon steel raised face slip-on flanges. This style has a concentrated sealing area and provides increased pressure capacity.

Single Bellows Floating Flanges

Floating flange (Van Stone) metal bellows expansion joints are provided with raised face or plate flanges with your required drilling pattern and are fully rotatable on each end of the joint. The necks of the bellows are flared to retain the flanges. Floating flange configurations allow for carbon steel flanges with all wetted components stainless steel or other alloys. Floating flanges also allow for easy bolt hole alignment in the field.

Combination of Flange Types

Metal bellows expansion joints are often constructed with a combination of flange types. Regardless of your needs, our craftsman can assemble the joint to your specifications. Combination of flange types allows for multiple installation types and increased compatibility.

Universal Tied Dual Metal Bellows

Universal tied metal bellows expansion joints have tie rods designed into the unit, making them capable of absorbing larger lateral movements than standard single joints. By adding the tie rods, the pressure thrust is restrained. The pressure balanced expansion joint will not accept external axial movement without overcoming this pressure thrust force. Available with optional liners or covers.

Externally Pressurized Metal Bellows

Externally pressurized metal bellows feature an anti-squirm design and can handle large axial movements. This is an exceptional product for absorbing large amounts of axial movement in long, straight pipe runs. One of the safest and most reliable joints, the unique design features make this an appealing option for steam and condensate applications.

Hinged Metal Bellows

A hinged metal bellows expansion joint is designed to permit angular rotation in only one plane by using a pair of pins through hinge plates attached to each end of the expansion joint. Hinge hardware and pins are designed to restrain pressure thrust of the bellows and any extraneous forces where applicable. Hinged metal expansion joints must be used in sets of 2 or 3 to function properly and they do not need to be co-linear.

Gimbal Pipe Metal Bellows

A gimbal pipe metal expansion joint is designed to permit angular rotation in any plane by using two pairs of hinges attached to a common floating gimbal ring/box. The gimbal ring/box, hinge arms and pins are designed to restrain pressure thrust of the bellows and any extraneous forces where applicable. Typical gimbal systems consist of 2 gimbal expansion joints or 2 gimbal and 1 hinge expansion joints. Just as hinged expansion joints offer great advantages in single plane applications, gimbal expansion joints are designed to offer similar advantages in multi-plane systems. Since gimbal expansion joints are not restricted to single plane systems, they have greater flexibility of usage.

Elbow Pressure Balance Units

This elbow pressure metal expansion joint is designed to not only restrain the pressure thrust, but in addition, balances the pressure thrust so as not to have anchoring of the adjacent piping or equipment. This pressure balanced elbow expansion joint can be designed as a single or universal depending on how much lateral movement is required.

Metal Pump Connectors

Flexible Metal Pump Connectors are designed with a flexible core of corrugated tin bronze or type 321 stainless steel tubing under the braid. Flat-face flanges are standard; however, other types are available. A wire braid is used over the flexible core on most designs to provide strength for the rated operating pressure.

Metal Engine Exhaust Bellows

Stainless Steel Engine Exhaust Expansion Joints are manufactured from a thin-gauge stainless steel tube. This tubular body is formed into corrugations forming a bellow providing a highly flexible and durable connector for the extremes of exhausting engine gases.

Benefits of Metal Expansion Joints

- Vibration Isolation: unnecessary vibration in piping systems can cause severe damage to the system and surrounding equipment.

- Wide Temperature & Pressure Rages: metal expansion joints can handle a wide range of hot and low temperatures, conveying liquids, solids and abrasive materials. They also offer high pressure ratings.

- Low Maintenance: Metallic expansion joints require very little maintenance when constructed of durable, corrosion-resistant materials and offer a long life cycle.

Metal Bellows Type Expansion Joints and Pump Connectors are for use in pipelines and process vessels to absorb motion in the system. Our products incorporate the latest recommendations of the Expansion Joint Manufacturers Association.

- Absorbs damaging vibrations in piping systems

- Absorbs mechanical movements

- Space-saving options

- Low maintenance requirements

- Multiple variations and configurations

- Corrosion-resistant

- Abrasion-resistant

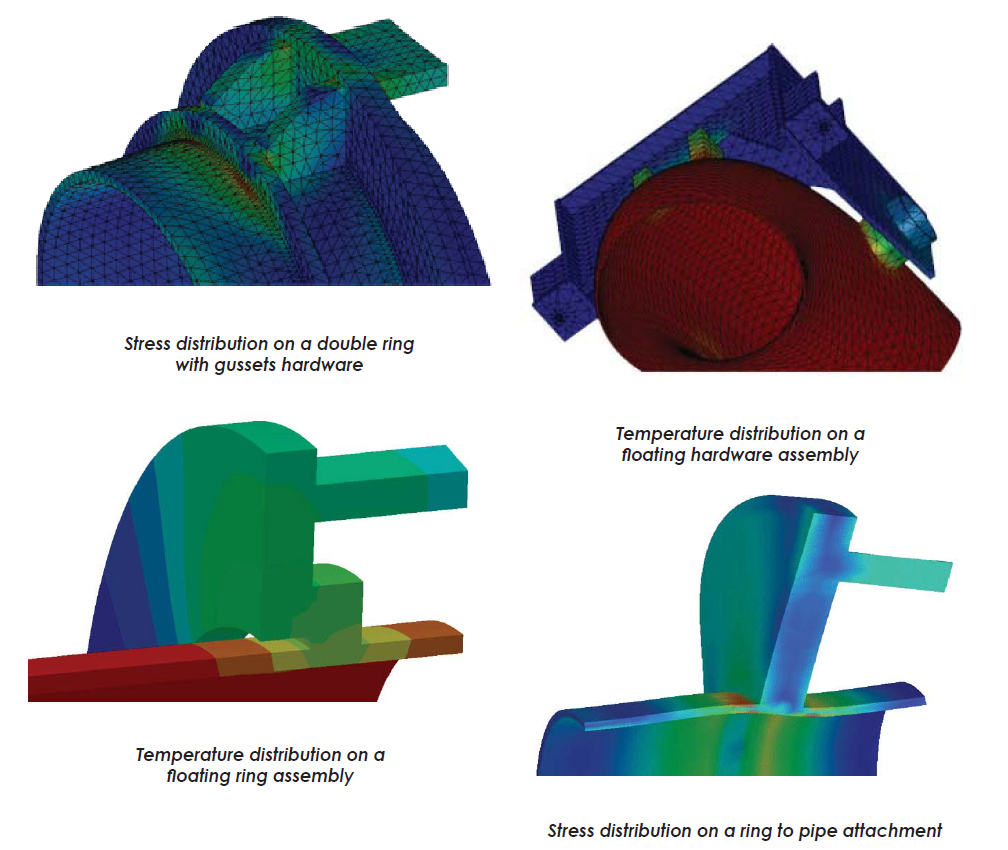

Engineering Capabilities

UIP utilizes various engineering software programs to provide expansion joints in accordance with customer requirements for the utmost reliability. Some of these programs are industry-leading programs such as Finite Element Analysis (FEA) CAD/CAM and Expansion Joint Manufacturers Association (EJMA). Our products are fully engineered to industry accepted standards.

Industry Codes

UIP Expansion Joints are manufactured in accordance with EJMA’s latest edition. Other industry standards that UIP Manufacturing can conform to, but are not limited to, include:

• ASME B31.3

• ASME B31.1

• MIL-I-45208

• MIL-Q-9858

• U.S. Coast Guard requirements

Bellows Material Specification

UIP standard bellows material is A/SA240 321ss. Other materials available to UIP to

manufacture bellows include:

• A/SA240 304SS

• A/SA240 304LSS

• A/SA240 316SS

• A/SA240 316LSS

• A/SA240 310 S

• B/SB444 Alloy 625 (Inconel® 625)

• B/SB168 Alloy 600 (Inconel® 600)

• B/SB575 Alloy C276 (Hastelloy® C276)

• B/SB575 Alloy C22 (Hastelloy® C22)

• B/SB127 Alloy 400 (Monel® (400)

• B/SB409 Alloy 800

• Duplex Alloy 2205

• Hastelloy® X

• Nickel 200

• Alloy 20

• AL6XN

UIP welders are qualified in accordance with ASME Section IX latest edition (procedures available for review upon request). We stock various types of bellows materials, flanges, plates, pipe and threaded rods for fast response and delivery times.