Gasket Types, Materials & Applications

What is a Gasket?

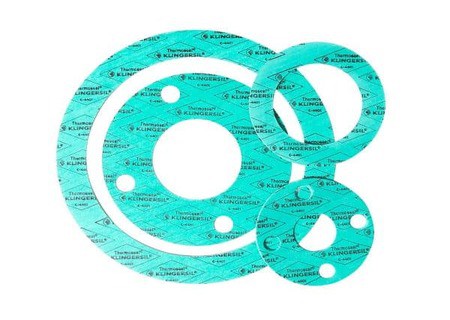

Gaskets are thin components that form a pressure-tight seal between two surfaces. They take the form of rings or sheets that fit between a variety of joints and mating surfaces. Gaskets are available in a wide range of materials to suit varied industrial needs, with common options including rubber, cork, metal, foam, paper, and more.

Gaskets are typically used to prevent liquids or gases from leaking out of a system. They are designed to resist fluctuations in pressure and temperature as well as electrical or electromagnetic forces, ensuring a durable seal across environments. In addition to preventing leaks, gaskets are also useful for dampening vibration, reducing sound, and sealing against contaminants.

Despite their simple construction and installation, gaskets are critical components for protecting mechanical systems. Not only do gaskets prevent leaks into or out of systems, but they also minimize wear, dampen noise, and maintain a more hygienic environment.

Although gaskets form tight seals, they are not appropriate for all sealing applications, and they should not be confused with O-rings or other general-purpose seals. Gaskets are meant to be used in static settings and provide the best seal under compression. Applications with moving parts such as motors, engines, and rotary shafts require more versatile sealing components.

At UIP, we manufacture a wide range of stocked and custom cut gaskets designed to meet a variety of industrial requirements. Whether your application involves high temperatures, strong vibrations, or strict sanitation standards, UIP can deliver precision-cut gaskets for your needs.

How Do Gaskets Work?

Gaskets are designed to fill deformities and connect two specific mating surfaces. These surfaces create a compressive force that seals the gasket into place. Once fitted, this compression allows the gasket to maintain its seal despite changing conditions.

GASKET MATERIALS

Gaskets must be able to maintain a static seal under diverse operating conditions, including at temperature and pressure extremes. Choosing the right gasket composition helps ensure that seals perform well in all required environments.

The most common gaskets in standard applications, non-metallic gaskets are made from materials such as rubber, Teflon, graphite, or compressed non-asbestos fiber (CNAF). They compress easily and are flexible enough to fill deformities, so they are ideal for sealing uneven surfaces. Although most non-metallic materials are not suitable for use in high-pressure or high-temperature settings, a few non-metals can withstand more extreme operating conditions. Graphite gaskets, for instance, can withstand temperatures as high as 460° C.

Gasket Materials Available at UIP

UIP specializes in rubber elastomeric gaskets, including a vast range of FDA-grade and specialty options. We carry one of the largest selections of sheet rubber and gasket material in the industry. Contact Us today to find the right material selection for your application.

OTHER GASKET MATERIALS

Spiral Wound

PTFE/Teflon®

Cork

SPECIALTY

Phenolic

NSF 61 Certified EPDM

To learn more about these options, refer to our resource page on gasket material properties. Our engineering experts can also answer your questions and provide more individualized guidance.

Aerospace

Automotive

Chemical/Petrochemical

Spiral-wound, metal graphite, and PTFE gaskets provide superior performance for highly corrosive and high-temperature applications.

Electrical

Food Processing

Oil & Gas

Pharmaceutical

Pumping

Rail

Water/Drinking Water

CUSTOM GASKETS & CAPABILITIES

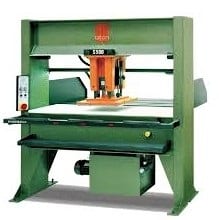

CNC Knife Cutting. Designed for quick turnaround of large-scale, non-metallic materials, the CNC Knife Cutting Machine uses advanced technology to ensure precision and accuracy on single or large production runs. Utilizing our CAD System we are able to build and customize any gasket design.

UIP International’s Gasket Expertise

Whether formed from metal, rubber, or a combination of materials, gaskets are essential for maintaining safe and hygienic equipment function.

As a premier gasket supplier, UIP takes pride in manufacturing quality gasket products that deliver the premium fluid sealing performance your business demands. As an ISO 9001:2015-certified company with strict quality control expectations, all of our products undergo rigorous quality inspections to ensure clients receive only the best.

To get started on your premium gasket project, request a quote from UIP International today.