TYPES OF EXPANSION JOINTS

UIP International offers an extensive range of premium quality expansion joints manufactured from all types of materials including high-grade elastomers such as EPDM, Neoprene & Nitrile, as well as PTFE, fabric, stainless steel, AL6XN, and other exotic alloys such as Inconel® and Hastelloy®. We also offer high temperature flue ducts and expansion joint sound absorbers.

Our combined technology expansion joint options are designed specifically for highly corrosive environments. Our designs comply with all current guidelines and the highest standards of the Expansion Joint Manufacturers Association and Fluid Sealing Association. There are many types of expansion joints, each offering unique properties suitable for different applications. Contact the expansion joint specialists today.

Rubber expansion joints are durable, lightweight, and capable of nearly unlimited flexing without damage. These properties make them ideal for handling high-pressure loads, minimizing noise and vibration, and compensating for misalignments during system operation. When installed in piping systems, rubber expansion joints help prolong the life of the piping and any connected equipment.

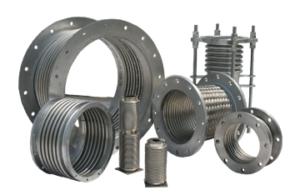

Metal Bellows Expansion Joints

Made from high-quality, corrosion-resistant metals such as stainless steel, InconeI%, or Hastelloy%, metal expansion joints are designed to provide long-lasting support in piping applications. They can tolerate a wide range of temperatures and pressures, making them ideal for conveying liquids, solids, and abrasive materials in harsh environments.

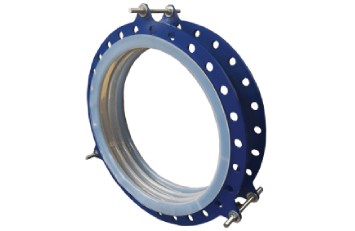

Teflon/PTFE Lined Expansion Joints

Polytetrafluoroethylene (PTFE) is a synthetic fluoropolymer known for its non-stick properties and resistance to various chemicals. Featuring a versatile space-saving design, Teflon/ PTFE-lined expansion joints are ideal for a range of corrosive, high-temperature, and high-pressure applications with space

Fabric expansion joints are non-metallic flue duct expansion joints, or flexible connectors, which provide stress relief for piping and ducting systems by absorbing thermal growth and shock, isolating mechanical vibration, and allowing for misalignments.

Offering dual containment and zero-leakage protection, FEP fluoroplastic expansion joints are a great choice for operations involving highly aggressive or corrosive media.

WHAT IS AN EXPANSION JOINT?

An expansion joint is a mechanical device designed to relieve the stresses generated by expansion, contraction, vibration, and other types of movement in pipelines. While these movements are unavoidable, expansion joints counteract the amount of strain they place on the piping system and minimize the risk of bowing, buckling, or pulling apart.

UIP International is one of the United States’ leading suppliers of high-quality Kadant-Unaflex® expansion joints. Designed by the industry’s top experts and available in rubber, PTFE/Teflon®, fabric, metal, and many other materials, our products can be used to support a wide range of applications.

Piping systems naturally expand and contract with changes in temperature, which creates stress at fixed points throughout the system and within the actual piping. While design features such as expansion loops can increase a piping system’s flexibility, the addition of expansion joints is a much more affordable and effective way to achieve flexibility while maintaining a compact design. Expansion joints safely absorb axial, lateral, and angular deflections and can tolerate the pipe’s internal pressures.

Some of the key benefits of installing expansion joints in a piping system include:

- Stress alleviation: In addition to relieving movement-related stresses within piping, expansion joints reduce unnecessary strain on connected equipment (e.g., pumps), which minimizes the risk of downtime and extends the service life of the piping system.

- Misalignment correction: Some expansion joints can compensate for various degrees of misalignment within the piping system, depending on their design. For example, custom expansion joints can include offsets that counteract installation- or settling-related pipe alignment issues.

- Abrasion resistance: Expansion joints can be made from a range of high-performance elastomeric materials that tolerate exposure to abrasive media.

- Vibration absorption: Fatigue-resistant rubber expansion joints can be installed in specific locations to absorb vibrations and oscillations.

- Noise attenuation: Expansion joints create a discontinuity between pipe materials, which helps minimize the transmission of mechanical noise.

- Shock absorption: Events such as pressure surges, water hammer, and pump cavitation can expose piping systems to various amounts of shock during operation. By absorbing these shocks, expansion joints help protect a piping system from cumulative damages that could shorten its service life.

- Reduced corrosion risk: Expansion joints reduce metal-to-metal contact within piping systems, eliminating the risk of corrosion when two dissimilar metals are joined.

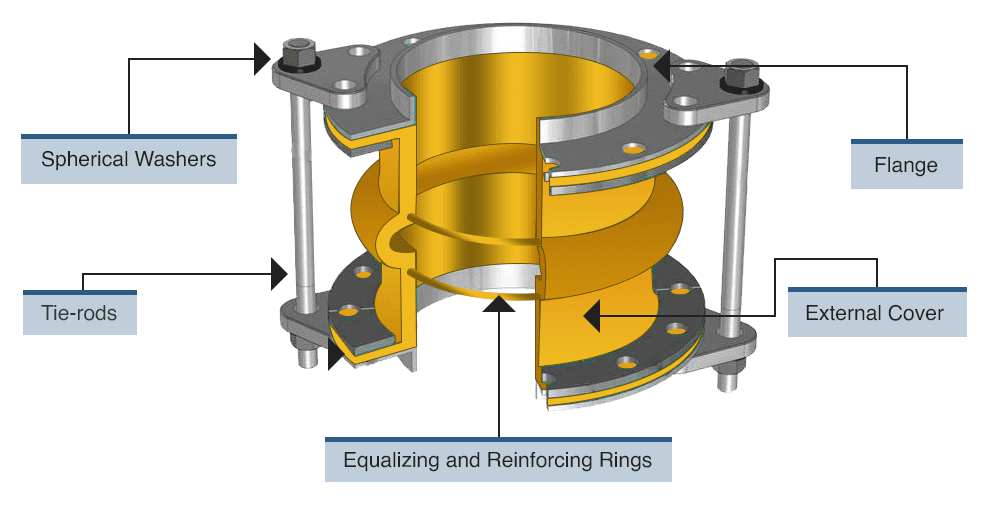

While the design of an expansion joint may vary from application to application, most include some combination of the following components:

- Inner sleeve

- External cover

- Insulation

- Bellows

- Welding ends

- Flanges

- Hinges

- Tie-rods

- Spherical washers

- Wire mesh

- Equalizing and reinforcing rings

INDUSTRIES & APPLICATIONS THAT USE EXPANSION JOINTS

Expansion joints are essential components of piping systems. They are often installed near boilers, pumps, heat exchangers, and other equipment to reduce pipe loads at connection points. Typical industries and applications that rely on them include:

- Architect and construction engineering

- Chemical and petrochemical processing

- Cryogenic processes

- Diesel engine manufacturing

- Gas turbine and gas transmission systems

- Heat recovery steam generators

- Pharmaceutical manufacturing

- Power generation and co-generation

- Pressure vessels

- Pulp and paper manufacturing

- Wastewater treatment

MATERIAL SPECIFICATIONS & MATERIALS TECHNOLOGY AT UIP

An expansion joint’s construction materials will strongly influence its suitability for specific applications. For example, rubber expansion joints are flexible, resilient, and extremely efficient at absorbing vibration, whereas metal expansion joints are stiffer but can handle much higher temperatures and pressures. The types of media being processed and their abrasiveness should also be considered when selecting a suitable material for your application.

Some of the commonly used expansion joint materials include:

- PTFE: PTFE is a synthetic fluoropolymer with hydrophobic properties, which allow it to repel water and water-based substances. Known for its chemical resistance and low coefficient of friction, PTFE performs well in applications involving reactive or corrosive chemicals.

- Kevlar@: Kevlar@ is a para-aramid synthetic fiber that is typically spun into durable ropes or fabric sheets. Offering a high tensile strength-to-weight ratio, Kevlar@ materials are ideal for high-temperature applications requiring a combination of durability and flexi bility.

- Neoprene: Neoprene is a synthetic rubber that provides resistance to heat, ozone, weather, alkalis, salts and acids. This material is often used in applications involving exposure to weather and temperatures of up to 250 F.

- Stainless steel: Stainless steels are steel alloys containing at least 10.5% chromium by mass. The corrosion resistance of stainless steels makes them ideal for applications involving harsh chemicals.

- Carbon steel: Carbon steel is characterized by a higher concentration of carbon relative to other steels. Its hardness and wear resistance make it well-suited for heavy-use or abrasive applications.

- InconeI@: Inconel@ is a family of nickel-based superalloys often used in high-temperature and

high-pressure applications.

At UIP International, we validate the performance of our expansion joint materials using a series of tests that are designed to replicate actual operating conditions. Material properties that are evaluated include:

- Abrasive and tear strength

- Chemical resistance

- Flexibility

- Heat convection

- Mechanical and tensile strength

- Post-compression recovery rate

- Temperature resistance

For more information, visit our Expansion Joint Materials Technology page.

PIPE EXPANSION JOINTS AT UIP INTERNATIONAL

Expansion joints play a critical role in allowing piping systems to experience movement without deforming or cracking. At UIP I nternational, we offer full-service engineering support for a range of material handling and piping system applications. Our extensive selection of expansion joints includes options made from high-grade elastomers and stainless steel and from specialty alloys such as Monel@, lnconel@, and Hastelloy@.

To ensure the aualitv of our Droducts. we maintain a strict aualitv control oroeram that comDlies with the latest ISO 9001:2008. MIL-1 -45208. and MIL-0-9858 standards. All expansion joints are designed in accordance with US Coast Guard requirements. In addition to our standard quality control testing, we also accept order-specific testing requests.

To learn more about our pipe expansion joint offerings, contact us or request a quote today.