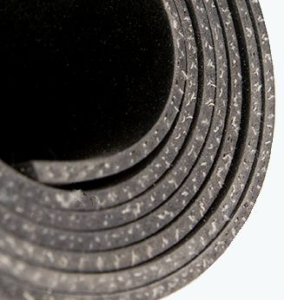

Cloth-Inserted Rubber – Benefits and Uses

There are several types of cloth-inserted rubber materials available, each offering its own unique benefits. Cloth-Inserted rubber consists of an elastomer such as SBR, Neoprene, or Nitrile/Buna-N, impregnated with one or more layers of fabric, usually polyester, nylon, cotton, or fiberglass. The fabric reinforcement significantly increases tear/tensile strength and provides high dimensional stability, while reducing gasket creep in flanged gasket applications with high compression loads.

UIP offers a variety of cloth-inserted rubber options in various widths and thicknesses, each with its own advantages. It is important to choose the right elastomer for your application. We are happy to help you determine the suitable product for your needs.

Sheet Type 87 Cloth-Inserted Neoprene:

Neoprene is an excellent all-purpose rubber with outstanding physical toughness. It offers heat, chemical, oil and ozone resistant properties and is a great choice for applications requiring maximum conformity and deformation resistance. The added 3.4 oz. nylon fabric makes it suitable for a variety of services including pads, chutes, rubber sleeves and safety guards. The inserted cloth reduces creep in seals and gasket services. Common applications of cloth inserted neoprene include meters, control devices, welding curtains, regulators, pumps, and diaphragms. It is suitable for use where petroleum, detergents and heavy oil resistance is required and works well in environments where hot or cold water and gases are being conveyed.

Sheet Type 88 Diaphragm-Inserted Neoprene:

With a 14.5 oz. Nylon insert, Diaphragm Inserted Neoprene has better tear resistance than any other cloth-inserted rubber. Used for applications requiring extreme fabric strength while still maintaining Neoprene’s excellent physical properties.

Sheet Type 98 Cloth-Inserted Nitrile/Buna-N:

Cloth Inserted Nitrile is the polymer of choice for dynamic applications requiring oil and solvent resistance. The 3.4 oz. nylon insert along with the properties of Nitrile rubber make it an excellent choice for applications requiring oil and gasoline resistance and superior resistance to petroleum-based hydraulic fluids. Common applications of cloth inserted nitrile rubber include fuel tank gaskets, conveyor belts, work surface areas, aviation fuel liners, diesel tank gaskets, weather stripping for automotive applications and many other applications that require fuel and environmental exposure.

Sheet Type 96 Nylon-Inserted SBR:

Nylon Inserted SBR Rubber increases durability and stability in high compression applications. Its good physical properties and abrasion-resistance make it an ideal choice for various air, hot water, low-pressure steam, and hydraulic services. Its low resistance to oil and gas makes it a poor choice for petroleum-based applications. Excellent stretch, tear and creep resistance. With resistance to abrasion and mild chemicals, it has use in outdoor and indoor projects.

Sheet Type 82 Fiberglass-Inserted Silicone:

Fiberglass inserted silicone sheeting is typically used for seals or gaskets requiring a non-porous material and high operating temperatures. It has excellent resistance to weather and oil deterioration and maintains flexibility at extreme temperatures. Ideally suited for gaskets, belting and diaphragm applications.

Call us today to find out about the wide range of sizes and materials we currently have in stock. Order by the roll, strip, cut piece or gasket.

2021

2021